Fabrication Equipment

Machine Parts Orders are fulfilled by Gulf States Saw & Machine Company. You only need to submit a form. We will immediately contact you to connect with a Parts Representative.

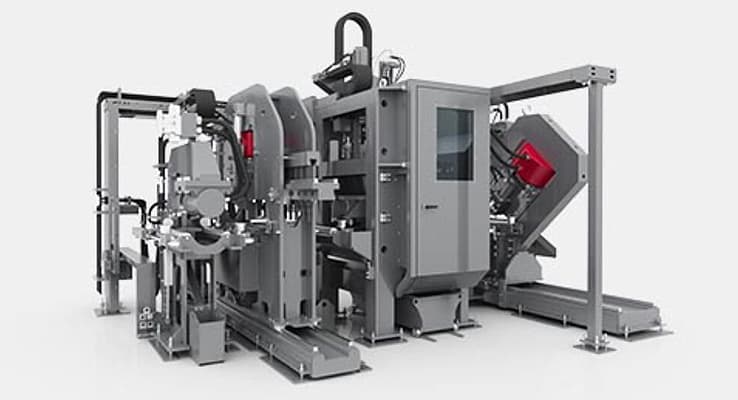

It is essential that you have reliable and high quality machines to help with your structural constructions. We have the right machines to help you achieve the best results with plate and beam fabricating. These machines include plates processors. beam drill line. angle masters. layout markers. beam cambering, straightening. and beam cabering machines.

We offer machine tool, robot systems, as well as other fabrication machines. We also believe in education and helping our customers stay competitive on a global level. We offer seminars and factory tours to keep you abreast of the latest manufacturing technology trends.

Machine Parts Orders are fulfilled by Gulf States Saw & Machine Company. You only need to submit a form. We will immediately contact you to connect with a Parts Representative.

Over the past 15 year, Gulf States Saw & Machine Company provided services to both manufacturers and fabricators. We support the Southern East Coast's most reputable lines with advanced fabrication and machine technology. We have a North Carolina and Florida office. This allows us support and sell the most advanced manufacturing technology.

Incepted in 1984, in Tampa, FL, Gulf States Saw & Machine Company was formed with the aim of assisting clients get superior products in the cut-throat metal fabrication sector. CMTís operations progressively expanded to service the entire south with additional showrooms in Atlanta, GA, and Dallas, TX. Capitalís presence is now felt in 12 states, namely, Florida, South Carolina, Virginia, Mississippi, Tennessee, Texas, Georgia, North Carolina, Alabama, Louisiana, Oklahoma, and Arkansas.

Gulf States Saw & Machine Company will also accept requests for Machine Parts. Please complete the following form. A Parts Representative will get back to you shortly

Reliable, high-quality machines are necessary for your structural fabrications. We have the right machines for you to achieve the best results in beam and plate fabrication. These machines include beam drills, beam processors, angle masters, beam drilling lines, beam cutting machines, layout markers and beam cambering.

Structural steel fabrication involves cutting, bending and welding steel to make a structure. Unlike various types of welding in which steel alloy is repaired or strengthened, steel fabrication is when pieces of steel are put together to form different structures that are usually of predefined sizes and shapes.

Structural fabrication refers to the cutting, bending, and assembling of steel to create different products.

And while different metal fabrication companies use different techniques, most rely on three basic processes: cutting, bending and assembling.